Thermal cameras are powerful tools for detecting heat signatures and identifying hazards in industrial environments. However, certain limitations can affect their accuracy and performance.

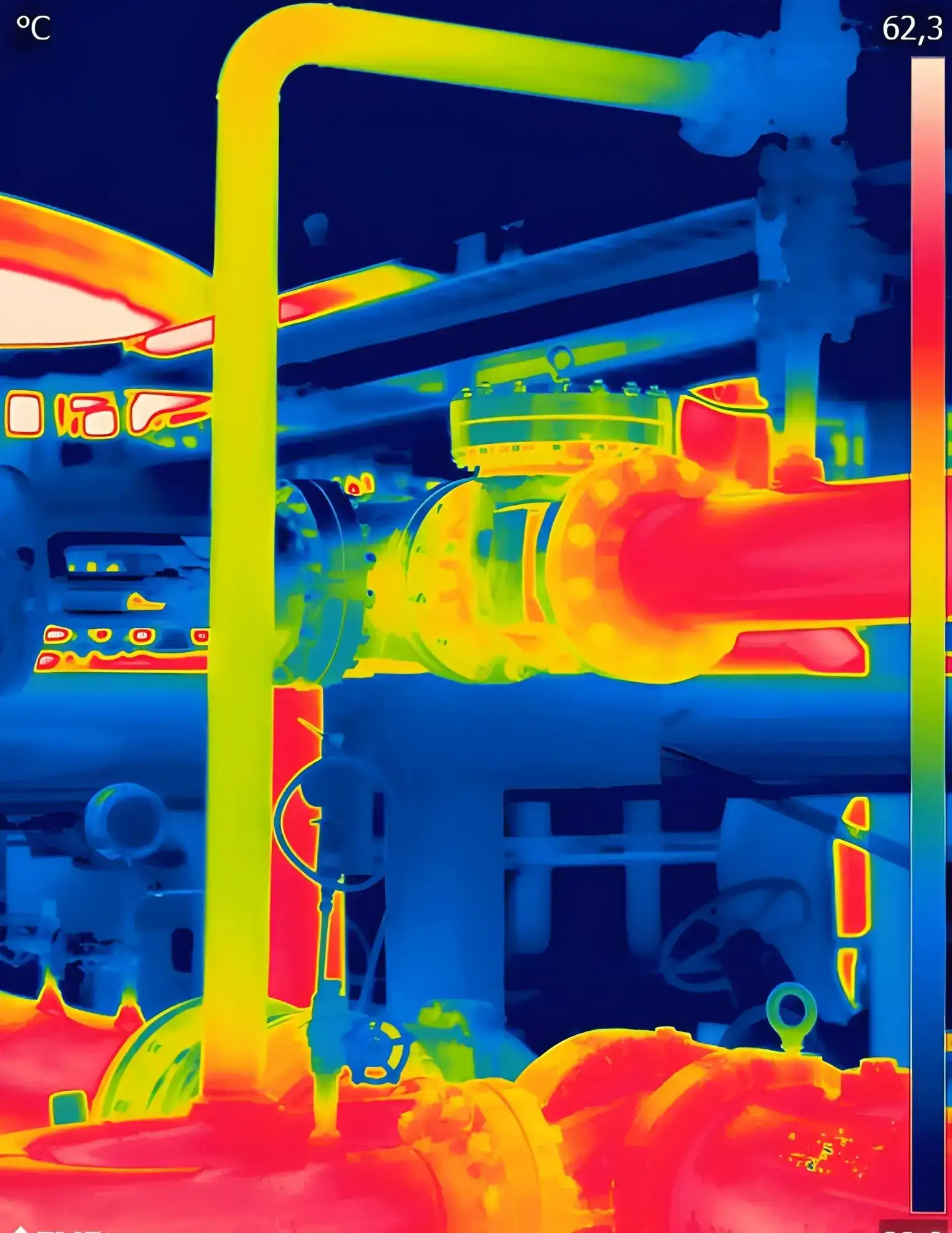

Environmental conditions such as fog, dust, rain, or steam can obscure infrared readings, making it harder to detect true temperatures. Reflective surfaces may also distort readings by bouncing thermal energy, leading to false interpretations.

Another challenge is thermal crossover. This occurs when the temperatures of different objects appear similar, reducing contrast in the thermal image. Without proper calibration and settings, the camera may fail to distinguish between safe and hazardous areas.

Distance and angle of view also impact accuracy. As distance increases, the resolution and thermal sensitivity decrease. To counter this, operators must select the right lens and position the camera appropriately.

Regular maintenance and calibration are crucial to ensuring consistent thermal performance. Advanced systems paired with analytics can compensate for many limitations.

By understanding these factors, users can deploy thermal cameras more effectively and make informed decisions in high-risk environments.